Planned A, B and C maintenance and unplanned maintenance of gas turbines and generators of all types and types are carried out by our expert team and the supervisors of the manufacturer with our tool containers.

During maintenance, occupational safety rules are applied at the highest standards as required by our company policy. Our company provides trainings to its employees in certain periods on this subject and ensures the awareness of each employee. Each employee is given the authority to stop the work if an inconvenience occurs.

In addition, the unit received from the customer, all kinds of measures taken to prevent loss of production in the schedule determined and delivered maintenance.

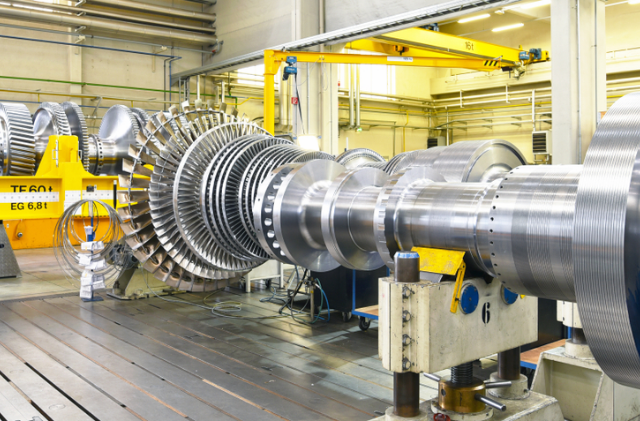

Maintenance of gas turbines

- Disassembly and assembly with turbine noise enclosure instruments,

- Taking all measurements before disassembly of turbine and generator,

- Turbine rotor disassembly and assembly,

- Gas turbines rotor and stator maintenance,

- Turbine rotor chemical cleaning processes or sand blasting of blades with dry ice,

- Eye control and maintenance of combustion chambers, change of ceramics and nozzles (burner),

- Disassembly, maintenance and assembly of turbine valves,

- Hot-Gas Path maintenance,

- Fixed-moving wings change,

- Control and maintenance of turbine bearings,

- Crack tests,

- Compressor section maintenance,

- Air Intake section maintenance and filter changes,

- Turbine coupling adjustment,

- Oil tanks, oil pumps and oil heat exchangers maintenance, oil changes

- Maintenance of auxiliary systems

- Dismantling and installation of turbine insulation

Maintenance and planned maintenance of gas turbines generators of all sizes (air-cooled or hydrogen-cooled):

- Manufacturing of rotor disassembly apparatus,

- Rotor disassembly and assembly,

- Generator rotor and stator chemical cleaning processes,

- Retaining ring disassembly and assembly, insulation control,

- Dismantling, maintenance and pressure tests of generator coolers,

- Control and maintenance of generator bearings,

- Generator warning system disassembly and maintenance,

- Generator, stator windings control, replacement and maintenance,

- Control and maintenance of rotor and stator insulation paints,

- Maintenance and installation of sealing rings,

- Maintenance of auxiliary systems,

- Meger test.

Electricity – I&C Maintenance and Calibration

With our Beamex MC5 calibration device, external calibration pumps (250 bar) and Ametek calibration furnace (650 Co), pressure transmitters, pressure switches, temperature switches can be calibrated and temperature measurement instruments such as thermocouple and RTD can be measured.

More Info

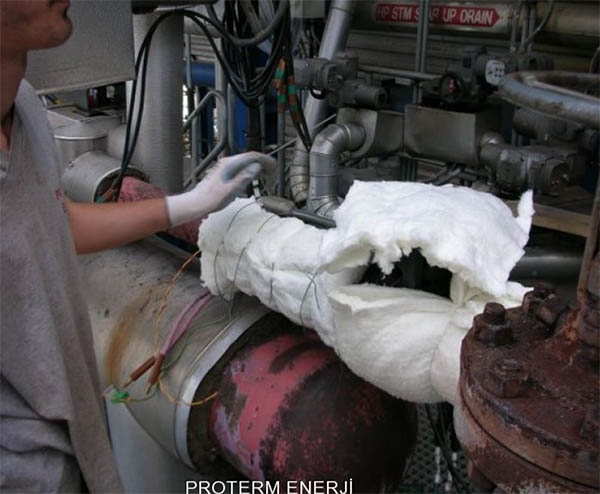

ISOLATION

In order to provide heat and sound insulation of turbines, we provide service in pillow insulation and spray insulation.

More Info

HEAT TREATMENT

With our Thermoprozess 48 KW heat treatment machines, tension relief and pre- & post Weld Heat Treatment (pre- and post-welding stress relief) applications are performed for all kinds of metal surfaces.

More Info

INDUSTRIAL SCAFFOLDING

In the power plants we serve, with our scaffolding team which has international certificates in planned and unplanned maintenance, we make scaffolding installation in all regions where we provide maintenance services such as boiler, turbine, chimney, air intake, auxiliary systems.

More Info